|

|||

|

Jeep FAQ How-To Articles Quick Reference Product Reviews My Buildup Random Home |

Electrical Repair / Diagnosing So after replacing a SilverStar headlight on the passenger side every 3 months or so, it was evident I had another problem. As you can tell my factory headlight harness had seen better days.

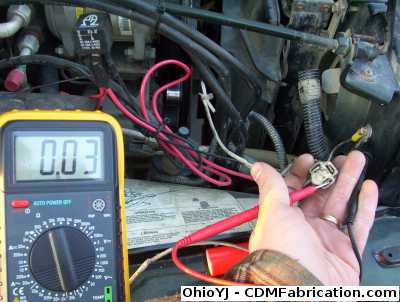

First step is to check the ground. With my meter set to read resistance, or ohms, I'm checking the ground pin of the headlight socket, to a a body ground right next to the harness. The meter reads 0.03, so very low resistance, the headlight should be well grounded. Time to move to the hot side.

I turned on the low beams, and measured the voltage on the low beam pin of the headlight socket. Bingo we have a problem, even after cleaning the connector the best I could on top, I could only get the meter to register 10.41 volts. Battery voltage with the Jeep off was about 12.2, so that would not be normal. I'm not getting full power for some reason.

Luckily headlight harnesses are readily available at most parts stores. Unfortunately after buying these $2 units, I found a much nicer set for only a few dollars more.

Now just to make sure my ground is good I'm going to add an extra ground into the ground side of the headlight when I add in the new harness. So I'll be combining these three wires here. Notice I'm only cutting one wire at a time on the headlight harness, I don't want to get them mixed up.

The only way to ensure the connection is a permanent connection is to solder it. This will help keep water and corrosion out of the connection. On a side note, soldering irons should not smoke excessively like the picture below, that one actually caught fire shortly after taking that picture, Luckily I had another one in the tool box.

Notice I've got pieces of heat shrink tubing on the wires before I soldered them. The heat shrink will help protect the connection, and it looks nice when its done.

While a heat gun is the preferred method to shrink the heat shrink tubing, I don't have one, so I typically hold a lighter underneath it.

Next to ensure this connection stays clean, I've used di-electric grease in the connector to keep moisture out of it.

Now time to check the harness. 12.18 volts, that's much better than 10.41, and my headlights are much brighter as well now.

Also during this I added an extra body ground to my Jeep. Just a simple 10 gauge wire from the battery to a bolt on my fender, just to ensure I had a good body ground.

© Copyright 2006 - 2025 Mike Lee

|

|

|