|

|||

|

Jeep FAQ How-To Articles Quick Reference Product Reviews My Buildup Random Home |

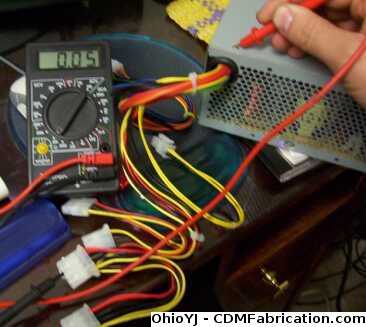

Ok so your Jeep won't start, but why, is the battery dead? For some reason people see meters as some mystical complicated device. Anyone who works on Jeeps should own a meter, and know how to use it. A meter can tell you if your battery is good, alternator is charging, if there is a break in a wire, if something is a good connection, test sensors like TPS/MAP/Crank/etc., and many other things. This is only meant to be a very basic outline, there will be no technical terms or theories, just how to use the meter. I have three examples of meters here, the one on the left cost $10, the one in the middle cost me $20, and the one on the right cost me $35. I'm going to recommend the one in the middle, it's a basic digital multi-meter. The cheap one will get you by, but it's harder to tell exact voltages on that analog display. Since I'm recommending the middle one, that's the one I'll use.  First thing is to check voltage. Jeeps run off a DC system, and are generally 12 volts, therefore I switch the meter to DCV (DC Volts) 20 (no more than 20 volts).  Black to negative, Red to positive. Its cold and rainy outside, so I don't have any picture of this on a Jeep battery, so I'm using a PC power supply as an example. I touch the black to the ground, red to the positive, and my "Jeep battery" shows 12.57 volts.  With the Jeep off a battery should show roughly 12.5 volts. When cranking the motor, the battery should hold a voltage of at least 10.5, nothing less. If it is less your battery is run down, dead, bad, or you have a bad starter. When running your alternator should put out between 14-15 volts, generally shouldn't be less or more. Want to check for voltage say to a fuse inside the Jeep. Touch the black lead to anything metal, a seat bolt for example, for a ground. Touch the red lead to the fuse socket, (try both sides, only one side of a fuse socket is live without the fuse), should come up with 12 volts if it's live. The next important thing to understand is resistance. Measuring resistance with a meter can quickly tell you if a wire has a break in it, or if something is a good connection, etc. Again I'm going to try and keep this as easy as possible. When measuring resistance red and black doesn't matter, all the meter does is check for continuity. The symbol for Ohms is under the 20k there on the bottom. You can see I have selected 20k ohms for my tests, this will generally be fine for most tasks. Right now the meter is display 1___.___, this means infinity on this meter, or there is no continuity (the leads are not connected or touching in any way).  In the picture below, I'm essentially checking to see if the yellow wire and the black wire meet at some point. The meter reads infinity, or no continuity, so I know the yellow and black wires do not meet or touch at any point.  In this picture, I have the leads touching a black wire on each clip. The meter is reading 0.04, or very little resistance, meaning these wires do have continuity and are connected. All wires will have a little resistance, or loss, so the 0.04 reading is normal, some wires will have a little more, some will have a little less.  Next say I want to check for a ground? I have one lead on a known good ground, the black wire. Now I want to know if the power supply casing is grounded, so I touch the other lead (remember color doesn't matter) to the casing. Meter reads 0.05, very little resistance so the casing is grounded.  Don't get to hung up on the meter readings when measuring resistance, its pretty much infinity (1___.___ on this meter), or something close to 0 when there is continuity. Ok so now why do you need to understand resistance? Many sensors on Jeeps today work off changes in resistance. For example a TPS sensor generally works off resistance, as the pedal travels the sensor changes resistance. Many times when TPS sensors go bad, they can develop bad spots, checking resistance on the TPS, and cycling it through its motion will reveal any bad spots, as the resistance will jump at the bad spot. Other things do this too, some Crankshaft Position Sensors work off resistance, when the magnet gets close to something metal the leads will have continuity, when its not there won't be continuity.

© Copyright 2006 - 2025 Mike Lee

|

|

|